Titanium Cutting Boards: A Comprehensive Guide to Modern Kitchen Innovation

What are titanium cutting boards and are they a good choice for Australian kitchens? Titanium cutting boards are premium, non-porous kitchen surfaces ideal for Australian homes. Known for exceptional durability, hygiene, and knife-friendliness, they resist stains and bacteria better than wood or plastic. Perfect for health-conscious cooks looking to upgrade their kitchen essentials.

The kitchen is the heart of every home, and having the right tools can transform your cooking experience from mundane to exceptional. Among these essential tools, cutting boards play a crucial role in food preparation, affecting everything from knife longevity to food safety. In recent years, titanium cutting boards have emerged as a revolutionary alternative to traditional materials, promising unparalleled durability, hygiene, and performance.

If you're considering upgrading your kitchen arsenal or simply curious about the latest culinary innovations, this comprehensive guide will walk you through everything you need to know about titanium cutting boards. We'll explore their unique properties, compare them with traditional materials, and help you determine if they're the right choice for your cooking needs.

What Are Titanium Cutting Boards?

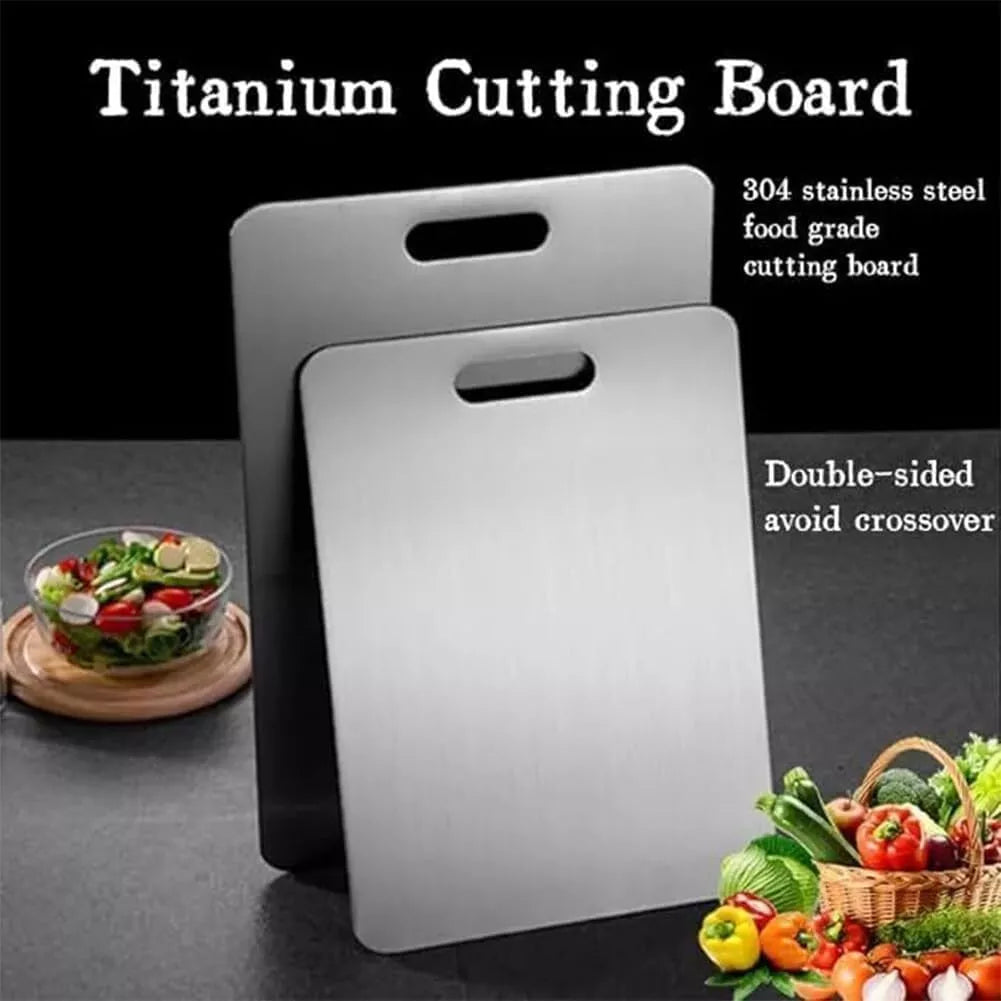

Terra Wellness Titanium cutting boards are food preparation surfaces crafted from high-grade titanium metal. Unlike conventional wooden or plastic boards, these modern alternatives leverage titanium's exceptional properties to create a cutting surface that addresses many common concerns associated with traditional materials.

Titanium is a remarkable metal known for its extraordinary strength-to-weight ratio, corrosion resistance, and biocompatibility. These same properties that make titanium ideal for aerospace applications and medical implants also translate to significant benefits in the kitchen. A typical titanium cutting board features a sleek, metallic surface that's completely non-porous and resistant to staining, odors, and bacterial growth.

Most quality titanium cutting boards are made from food-grade titanium with a purity level of 99% or higher. They often feature a brushed or matte finish that provides some texture for knife grip while maintaining ease of cleaning. Some models incorporate additional features like juice grooves, non-slip bases, or ergonomic handles for enhanced functionality.

The Science Behind Titanium's Cutting Board Superiority

Understanding the scientific properties of titanium helps explain why it performs exceptionally well as a cutting board material:

Material Hardness and Knife Edge Preservation

One of the most common concerns with metal cutting surfaces is their potential impact on knife edges. Interestingly, titanium strikes an impressive balance in this regard. On the Mohs hardness scale, titanium typically rates around 6, while the steel used in most kitchen knives ranges from 7-8. This means titanium is hard enough to withstand repeated cutting without excessive wear, yet soft enough not to cause significant dulling of knife edges.

In practical terms, this makes titanium cutting boards gentler on knives than glass, granite, or ceramic surfaces, while offering substantially greater durability than wood or plastic. The specific hardness of food-grade titanium allows it to withstand cutting pressure without causing the rapid dulling that occurs with harder surfaces.

Non-Porous Structure and Bacterial Resistance

Perhaps the most significant advantage of titanium cutting boards from a food safety perspective is their completely non-porous structure. Unlike wooden boards that contain microscopic pores where bacteria can hide and multiply, or plastic boards that develop knife grooves that harbor pathogens, titanium presents a seamless surface that bacteria cannot penetrate.

This non-porous quality means that food particles, liquids, and bacteria remain on the surface where they can be easily and completely removed during cleaning. Studies have shown that properly cleaned non-porous surfaces like titanium harbor significantly fewer bacteria than porous alternatives, reducing the risk of cross-contamination during food preparation.

Chemical Stability and Food Safety

Titanium is exceptionally stable and inert, meaning it doesn't react with food acids or leach any substances into your ingredients. This chemical stability ensures that your food remains uncontaminated during preparation, with no metallic taste transfer or chemical interactions. Even acidic foods like tomatoes, citrus, or vinegar-based marinades can be prepared on titanium surfaces without concern for material degradation or chemical reactions.

This inert quality makes titanium cutting boards particularly valuable for individuals with metal sensitivities or those concerned about potential chemical exposure from plastic cutting boards, which may contain BPA or other compounds of concern.

Key Benefits of Titanium Cutting Boards

Titanium cutting boards offer numerous advantages that make them increasingly popular among both home cooks and professional chefs:

Unmatched Durability and Longevity

The exceptional strength and wear resistance of titanium translate to cutting boards that can last a lifetime with proper care. Unlike wooden boards that can crack, warp, or develop deep grooves over time, or plastic boards that quickly accumulate knife marks and need frequent replacement, titanium boards maintain their integrity through years of daily use.

This extraordinary longevity makes titanium cutting boards a sustainable choice that reduces waste from disposable or short-lived alternatives. While the initial investment may be higher, the extended lifespan often makes them more economical in the long run compared to repeatedly replacing less durable options.

Superior Hygiene and Food Safety

Food safety concerns have driven many consumers to reconsider their cutting board choices, and titanium excels in this critical area. The non-porous surface prevents bacterial penetration and cross-contamination, while the material's resistance to cuts and grooves eliminates hiding places for pathogens.

Professional kitchens and health-conscious home cooks particularly value this aspect of titanium cutting boards. The ability to thoroughly sanitize the surface without concern for material damage provides peace of mind when preparing raw meats, seafood, or other potentially hazardous foods.

Effortless Maintenance

The low-maintenance nature of titanium cutting boards appeals to busy cooks who value convenience. Unlike wooden boards that require regular oiling and careful washing procedures, titanium boards can be quickly cleaned with soap and water or placed in the dishwasher without concern for warping, cracking, or other damage.

This ease of care extends the practical utility of titanium cutting boards, as they can be quickly sanitized between different food preparation tasks without the lengthy drying times or special treatments required by wooden alternatives.

Stain and Odor Resistance

Anyone who has used wooden or plastic cutting boards knows the frustration of lingering odors and stubborn stains from ingredients like garlic, onions, turmeric, or berries. Titanium's non-porous, non-reactive surface doesn't absorb food odors or discolor from contact with strongly pigmented foods.

This resistance keeps your cutting board looking and smelling fresh, even after preparing strongly flavored or colorful ingredients. The aesthetic longevity matches the structural durability, ensuring your titanium cutting board remains an attractive kitchen tool for years to come.

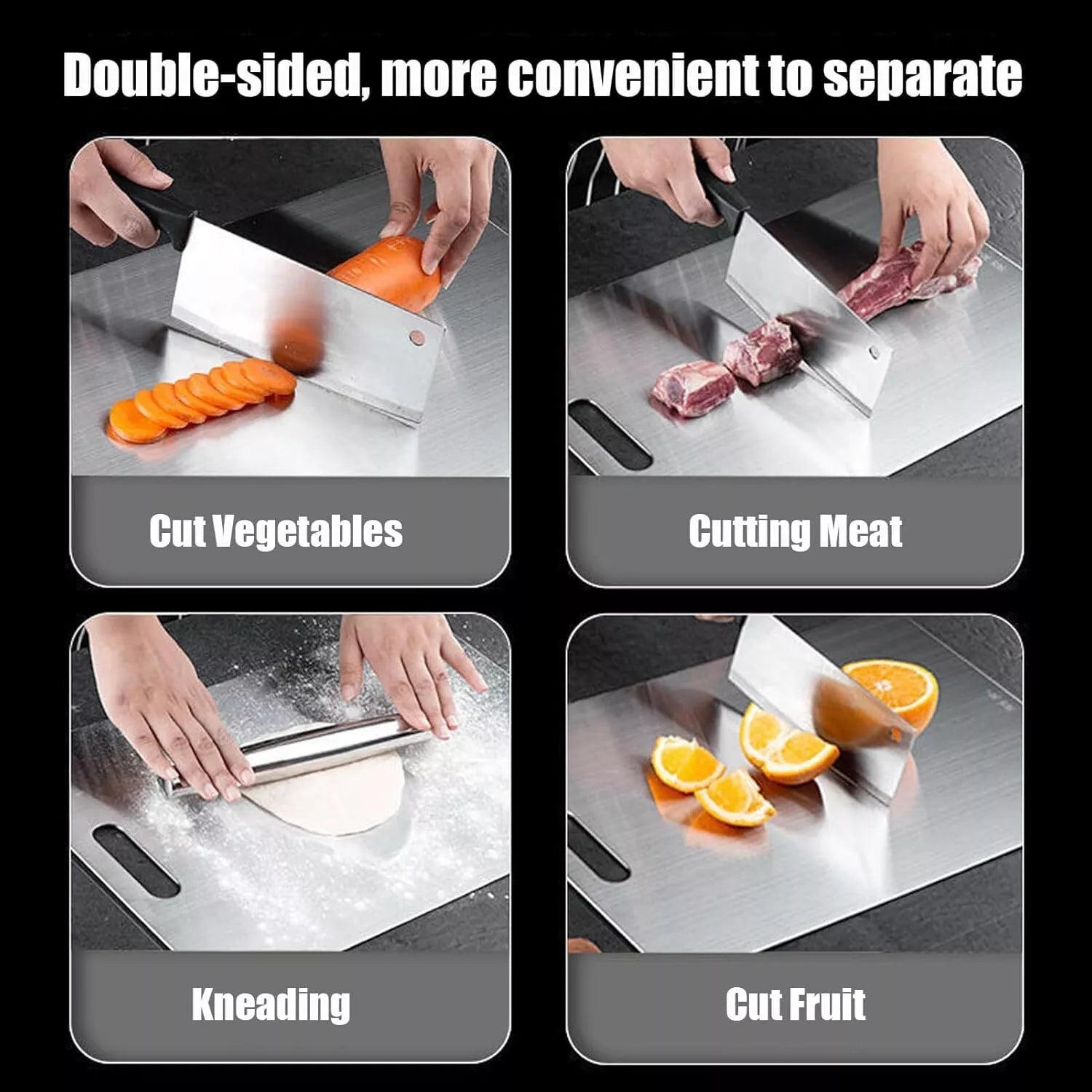

Versatility Beyond Cutting

Titanium cutting boards offer remarkable versatility in the kitchen. Beyond their primary function as cutting surfaces, they can serve as elegant serving platters, cooling racks for hot pans, or even impromptu pastry surfaces. Their heat resistance allows them to handle warm cookware without damage, expanding their utility beyond traditional cutting board functions.

This multi-functionality makes titanium cutting boards particularly valuable in smaller kitchens where space-efficient, multi-purpose tools are essential. Rather than storing multiple specialized items, a single titanium board can fulfill various roles with exceptional performance in each.

Potential Limitations of Titanium Cutting Boards

While titanium cutting boards offer numerous benefits, a balanced assessment should consider their potential limitations:

Initial Investment

Quality titanium cutting boards represent a significant upfront investment compared to wooden or plastic alternatives. Prices typically range from $80 to $200 depending on size and features, which may be prohibitive for some budgets. However, when considered as a long-term investment that eliminates the need for frequent replacements, the cost becomes more reasonable over time.

Weight and Handling

Though titanium is lighter than many metals, titanium cutting boards are generally heavier than plastic and some wooden boards. This additional weight provides stability during heavy chopping tasks but may be less convenient for frequent moving or storage. Some manufacturers address this by incorporating ergonomic handles or optimizing thickness to balance durability with manageable weight.

Sound Considerations

Cutting on a titanium surface produces more noise than cutting on wood or plastic. The metallic sound can be noticeable, especially during vigorous chopping. Some users address this by placing a thin silicone mat underneath the board to dampen sound, though this is an additional step not required with traditional materials.

Thermal Conductivity

While titanium has lower thermal conductivity than many metals, titanium cutting boards can still become cold in chilly environments, which some users find uncomfortable during extended food preparation. This property can be advantageous when working with temperature-sensitive ingredients like pastry dough but may be less comfortable for everyday chopping in cold kitchens.

Comparing Titanium to Traditional Cutting Board Materials

Understanding how titanium compares to other common cutting board materials helps put its benefits and limitations in context:

Titanium vs. Wood

| Feature | Titanium | Wood |

|---|---|---|

| Durability | Exceptional; doesn't warp, crack, or develop deep grooves | Moderate; susceptible to warping, cracking, and deep grooves |

| Hygiene | Superior; non-porous surface resists bacterial growth | Variable; natural antimicrobial properties but porous surface can harbor bacteria |

| Maintenance | Minimal; simple washing with soap and water | High; requires regular oiling and careful washing procedures |

| Knife Impact | Moderate; harder than wood but designed to minimize dulling | Minimal; naturally gentle on knife edges |

| Longevity | Decades or lifetime with proper care | 3-10 years depending on wood type and maintenance |

Titanium vs. Plastic

| Feature | Titanium | Plastic |

|---|---|---|

| Durability | Exceptional; resistant to cuts and scratches | Poor; quickly develops knife grooves and scratches |

| Hygiene | Superior; non-porous and resistant to bacterial growth | Moderate initially; declines as knife grooves develop |

| Maintenance | Minimal; dishwasher safe with no special care needed | Low; dishwasher safe but requires replacement as grooves develop |

| Environmental Impact | Low; extremely long lifespan reduces waste | High; frequent replacement and plastic waste concerns |

| Cost Efficiency | High long-term value despite higher initial cost | Low long-term value despite lower initial cost |

Titanium vs. Bamboo

| Feature | Titanium | Bamboo |

|---|---|---|

| Durability | Exceptional; virtually indestructible with normal use | Good; harder than many woods but still susceptible to cracking |

| Sustainability | Moderate; not renewable but extremely long-lasting | High; rapidly renewable resource with low environmental impact |

| Knife Impact | Moderate; harder than bamboo but designed to minimize dulling | Moderate to high; harder than many woods, can accelerate dulling |

| Maintenance | Minimal; simple cleaning with no special treatments | Moderate; requires oiling and careful washing |

| Aesthetic Appeal | Modern, sleek appearance | Natural, warm appearance |

Choosing the Right Titanium Cutting Board

If you're considering investing in a titanium cutting board, these factors will help you select the right one for your needs:

Material Quality and Certification

Look for boards made from high-purity titanium (99% or higher) with proper food-grade certification. Reputable manufacturers will provide information about material composition and safety testing. Be wary of vague descriptions that might indicate titanium-coated products rather than solid titanium construction.

Size and Thickness Considerations

Titanium cutting boards come in various sizes to suit different kitchen needs:

- Small (approximately 12"×8"): Ideal for quick tasks or smaller kitchens with limited counter space

- Medium (approximately 14"×10"): Versatile size suitable for most everyday cooking needs

- Large (approximately 18"×12"): Perfect for serious home cooks who prepare larger meals or work with larger ingredients

Thickness is equally important—look for boards at least 0.8mm thick to ensure adequate durability without excessive weight. Some premium models feature variable thickness with reinforced edges for optimal performance and handling.

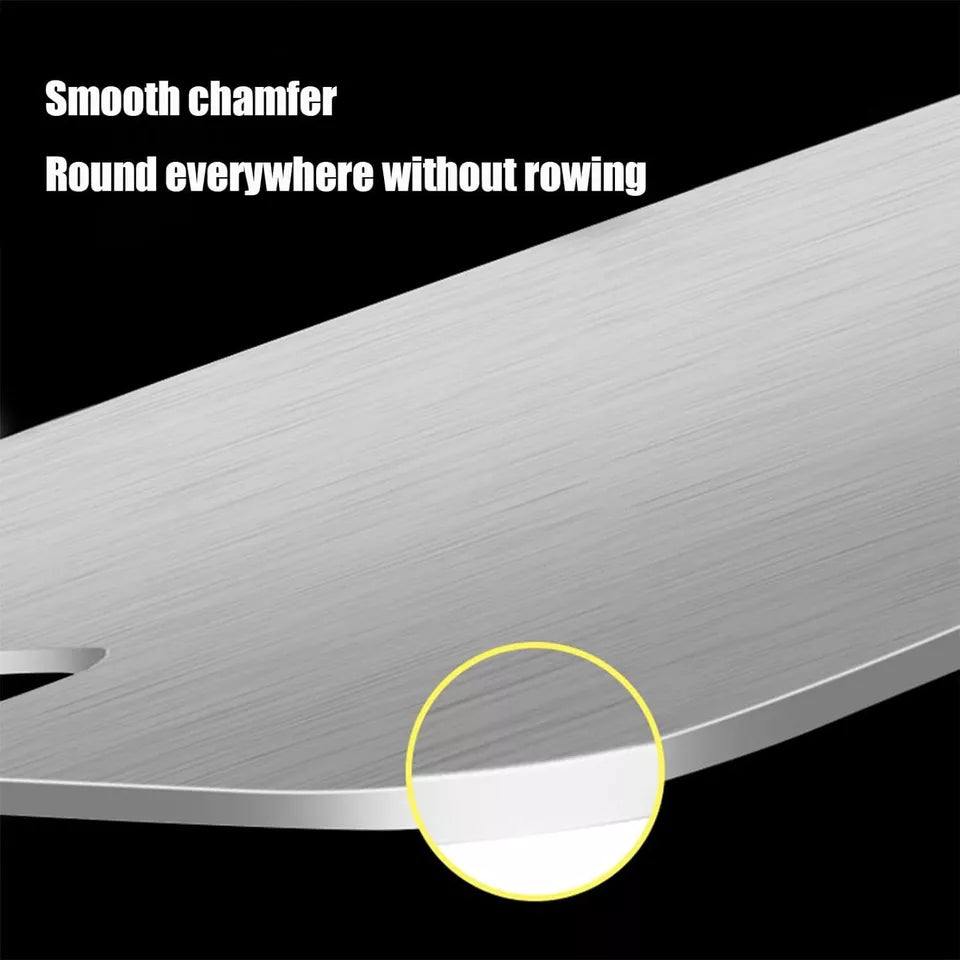

Surface Finish and Texture

The ideal titanium cutting board has a slightly textured surface that provides some grip for foods and knives without being rough enough to trap food particles. A brushed or matte finish typically offers the best balance between functionality and ease of cleaning. Avoid highly polished surfaces that may be too slippery for safe cutting.

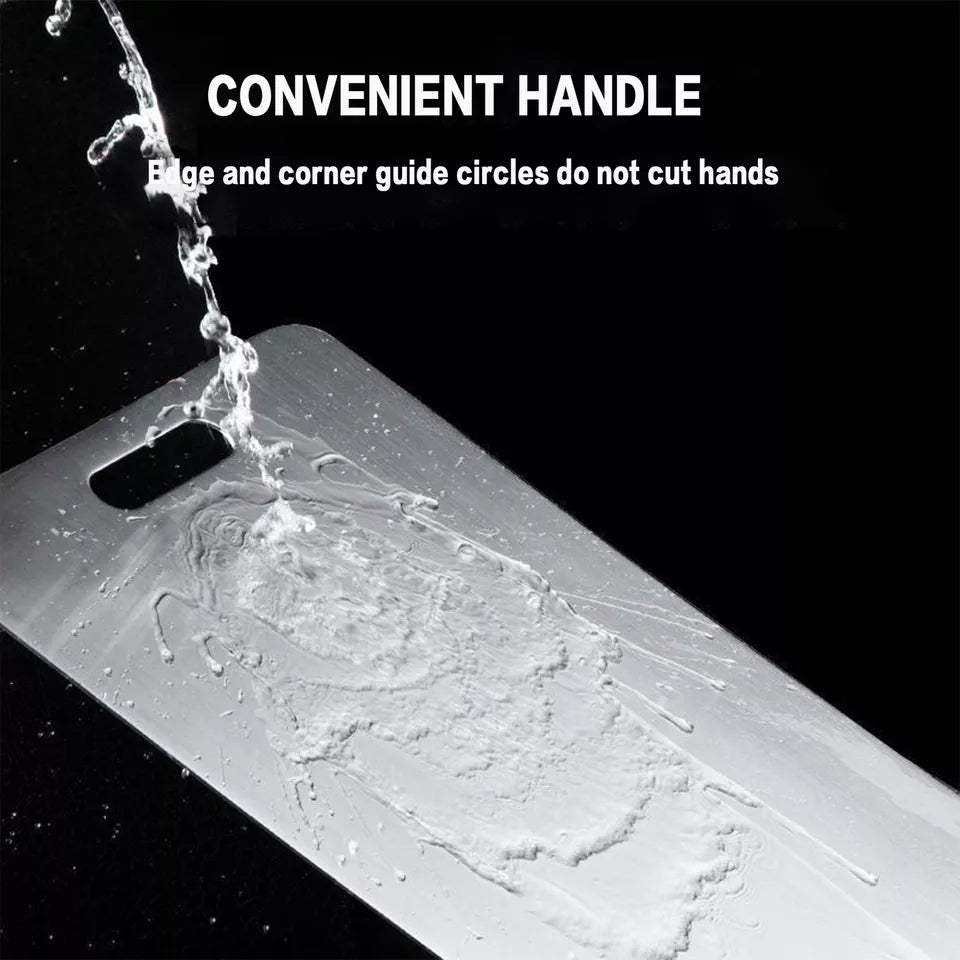

Edge and Corner Design

Quality titanium boards feature smoothly finished edges and corners that prevent discomfort during use and reduce the risk of scratches or cuts during handling. Some designs incorporate rounded corners or silicone edge guards for additional safety and comfort. These details significantly impact the overall user experience and should not be overlooked.

Additional Features

Consider whether you'd benefit from features like:

- Juice grooves: Channels around the perimeter to contain liquids from fruits or meats

- Non-slip base: Silicone feet or backing to enhance stability during use

- Integrated handles: Ergonomic cutouts or extensions for easy lifting and transport

- Hanging holes: For convenient vertical storage to save counter and cabinet space

Proper Care and Maintenance of Titanium Cutting Boards

One of the major advantages of titanium cutting boards is their minimal maintenance requirements. Follow these simple guidelines to keep your titanium cutting board in optimal condition:

Routine Cleaning

After each use, wash your titanium cutting board with warm water and mild dish soap. A soft sponge or cloth is typically sufficient for removing food residue. Unlike wooden boards, there's no risk of water damage or warping, so thorough rinsing is perfectly safe. Dry with a clean towel or allow to air dry completely before storing.

Dealing with Stubborn Residue

For sticky or stubborn food residue, a gentle scrub with a non-abrasive sponge is usually sufficient. For more persistent issues, a paste of baking soda and water applied with a soft cloth can help remove residue without scratching the surface. Avoid abrasive cleaners or steel wool, which may damage the finish.

Sanitizing Procedures

While titanium's non-porous surface naturally resists bacterial growth, periodic sanitizing is still good practice, especially after preparing raw meat or fish. You can safely use:

- Diluted bleach solution (1 tablespoon of bleach per gallon of water)

- Hydrogen peroxide

- White vinegar

- Commercial food-safe sanitizing sprays

Apply your chosen sanitizer, allow it to sit briefly according to product instructions, then rinse thoroughly and dry. Titanium's chemical resistance ensures these sanitizing agents won't damage the material.

Storage Recommendations

Store your titanium cutting board in a dry, upright position to allow air circulation and prevent potential scratches from stacking with other kitchen tools. Many titanium boards include hanging holes for convenient vertical storage, which saves counter and cabinet space while allowing the board to dry completely between uses.

Frequently Asked Questions About Titanium Cutting Boards

Are titanium cutting boards really better for knives than other metal surfaces?

Yes, quality titanium cutting boards are significantly gentler on knife edges than other metal surfaces like stainless steel, glass, or stone. This is because titanium has a lower hardness rating than the steel used in most kitchen knives, creating less friction and impact during cutting. While no metal surface is as gentle as end-grain wood, titanium offers a reasonable balance between durability and knife preservation.

Can titanium cutting boards rust or corrode?

No, titanium is highly resistant to rust and corrosion, even when exposed to moisture, salt, or acidic foods. This resistance is one of titanium's defining characteristics and a key reason for its use in marine and aerospace applications. Your titanium cutting board will maintain its appearance and performance without developing rust or corrosion spots, even with daily use and washing.

Are there any foods I shouldn't prepare on a titanium cutting board?

Titanium cutting boards are suitable for preparing virtually all foods, including those that might damage or stain other materials. Acidic ingredients like tomatoes, citrus, and vinegar; strongly pigmented foods like berries and turmeric; and proteins like raw meat and fish can all be safely prepared on titanium surfaces without concern for material damage or contamination.

How do titanium cutting boards compare to copper antimicrobial surfaces?

While copper has natural antimicrobial properties that actively kill bacteria, titanium's primary hygiene benefit comes from its non-porous nature that prevents bacterial penetration and growth. Copper cutting boards can react with certain foods and develop a patina over time, while titanium remains stable and non-reactive. For most home cooks, titanium offers a more practical balance of hygiene, durability, and maintenance.

Can titanium cutting boards be recycled?

Yes, titanium is 100% recyclable, though the extraordinary durability of titanium cutting boards means recycling would likely only be necessary after decades of use. If you eventually decide to replace your titanium cutting board, check with local metal recycling facilities that handle titanium. The material's value ensures it can be repurposed rather than ending up in a landfill.

Conclusion: Are Titanium Cutting Boards Worth the Investment?

Titanium cutting boards represent a significant advancement in kitchen tool technology, offering exceptional durability, hygiene, and convenience that address many limitations of traditional materials. Their non-porous surface eliminates concerns about bacterial contamination, while their remarkable longevity means they'll likely be the last cutting board you'll ever need to purchase.

The decision to invest in a titanium cutting board ultimately depends on your specific cooking habits, preferences, and priorities. If you value long-term durability, minimal maintenance, and superior hygiene, a titanium cutting board represents a worthwhile investment that will serve you well for years to come. The higher initial cost is offset by the extended lifespan and reduced need for replacement, making titanium cutting boards economically sensible for serious cooks.

For those who prepare food frequently, appreciate innovative kitchen tools, or have concerns about the hygiene limitations of traditional cutting boards, titanium offers a compelling alternative that combines the best aspects of various materials without their significant drawbacks. As with any premium kitchen tool, the value comes not just from the material itself, but from the improved cooking experience and peace of mind it provides day after day.

Whether you're a professional chef or a home cooking enthusiast, a titanium cutting board represents a modern solution to age-old kitchen challenges, bringing space-age material science to the heart of your daily food preparation routine.

Use code BLOG20 to save 20% today on our premium hygienic chopping boards, with free shipping Australia-wide. [Shop Hygienic Chopping Boards ➜]

FAQs About Titanium Cutting Boards (Australia)

Q1: What are the benefits of titanium cutting boards in Australia?

A: Titanium cutting boards offer unmatched durability, hygiene, and easy cleaning. They don’t absorb stains or bacteria, making them ideal for Australian households focused on food safety.

Q2: Are titanium cutting boards safe for kitchen knives?

A: Yes, titanium cutting boards are designed to be gentle on knives while still being resistant to wear—making them a smart balance between durability and knife preservation.

Q3: How do titanium cutting boards improve hygiene?

A: Their non-porous surface resists cuts and grooves, preventing bacteria from settling in. This makes them more sanitary than wood or plastic options.

Q4: Can titanium cutting boards rust in Australia’s humid kitchens?

A: No. Titanium is naturally corrosion-resistant, even in humid or coastal environments common in Australia.

Q5: Are titanium cutting boards eco-friendly?

A: Yes. They are fully recyclable and incredibly long-lasting, which means less waste compared to frequently replaced plastic or wood boards.

For further information please refer to:

Titanium or Stainless Steel Chopping Boards?

What Are the Most Hygienic Chopping Boards? Top Picks for a Clean Kitchen